Bending Force Calculator

Required Force:

Minimum Bending Tool Resistance:

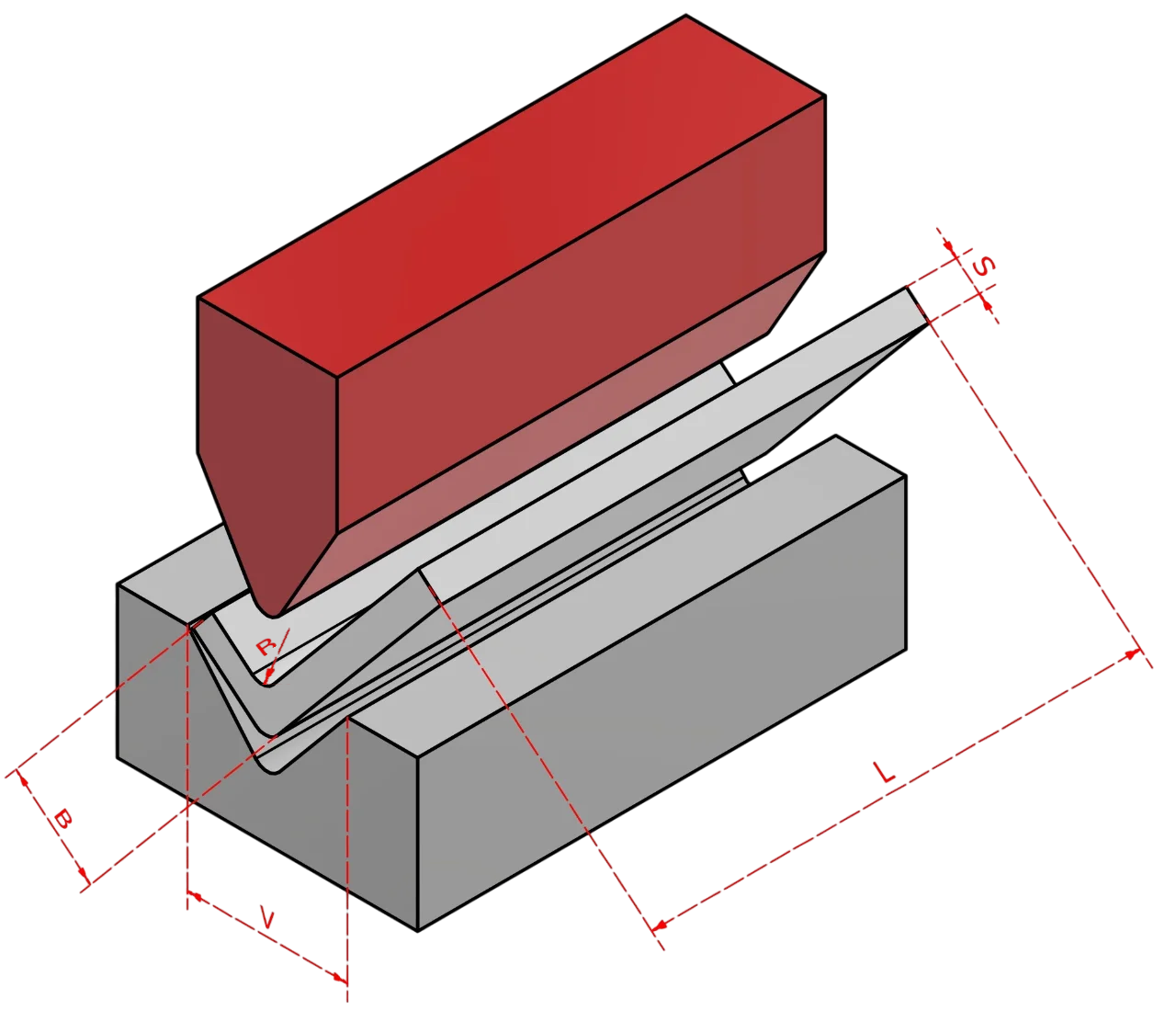

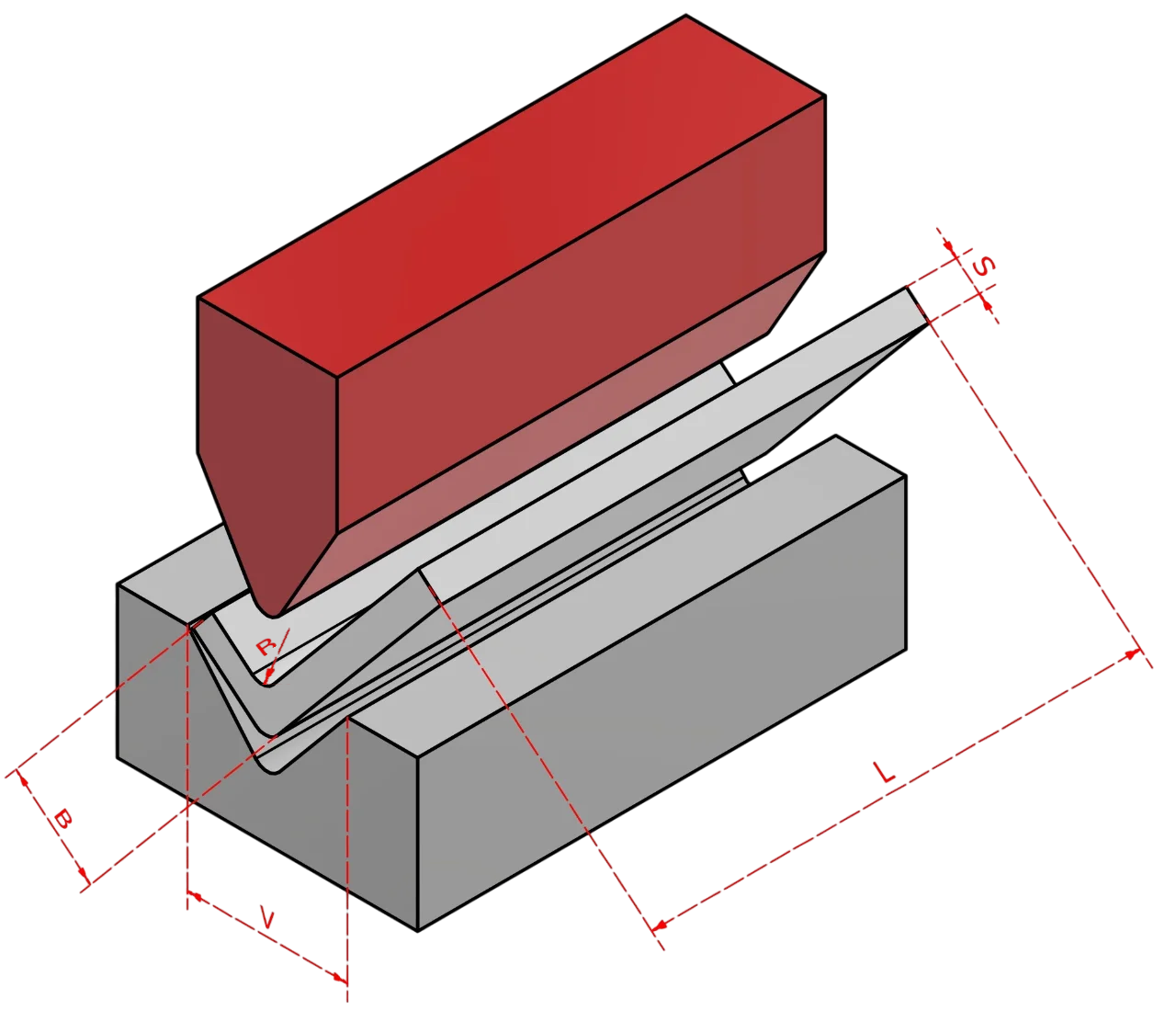

Minimum Flange Length (B):

Minimum Inside Radius (R):

Required Force:

Minimum Bending Tool Resistance:

Minimum Flange Length (B):

Minimum Inside Radius (R):

The Bending Force Calculator provided by FORZA Laser is designed to provide reference estimates based on standard formulas and typical material values. The results obtained should be considered as an initial guide and not as definitive values for industrial or critical engineering applications. It is highly recommended that you consult with a specialized technician or engineer before making any decisions based on these calculations, as there may be additional factors influencing actual results, such as specific working conditions, material tolerances, manufacturing variations, and regulatory requirements. The availability of this resource does not replace professional advice.